Table of Contents

The Basics of 60947 4 contactor

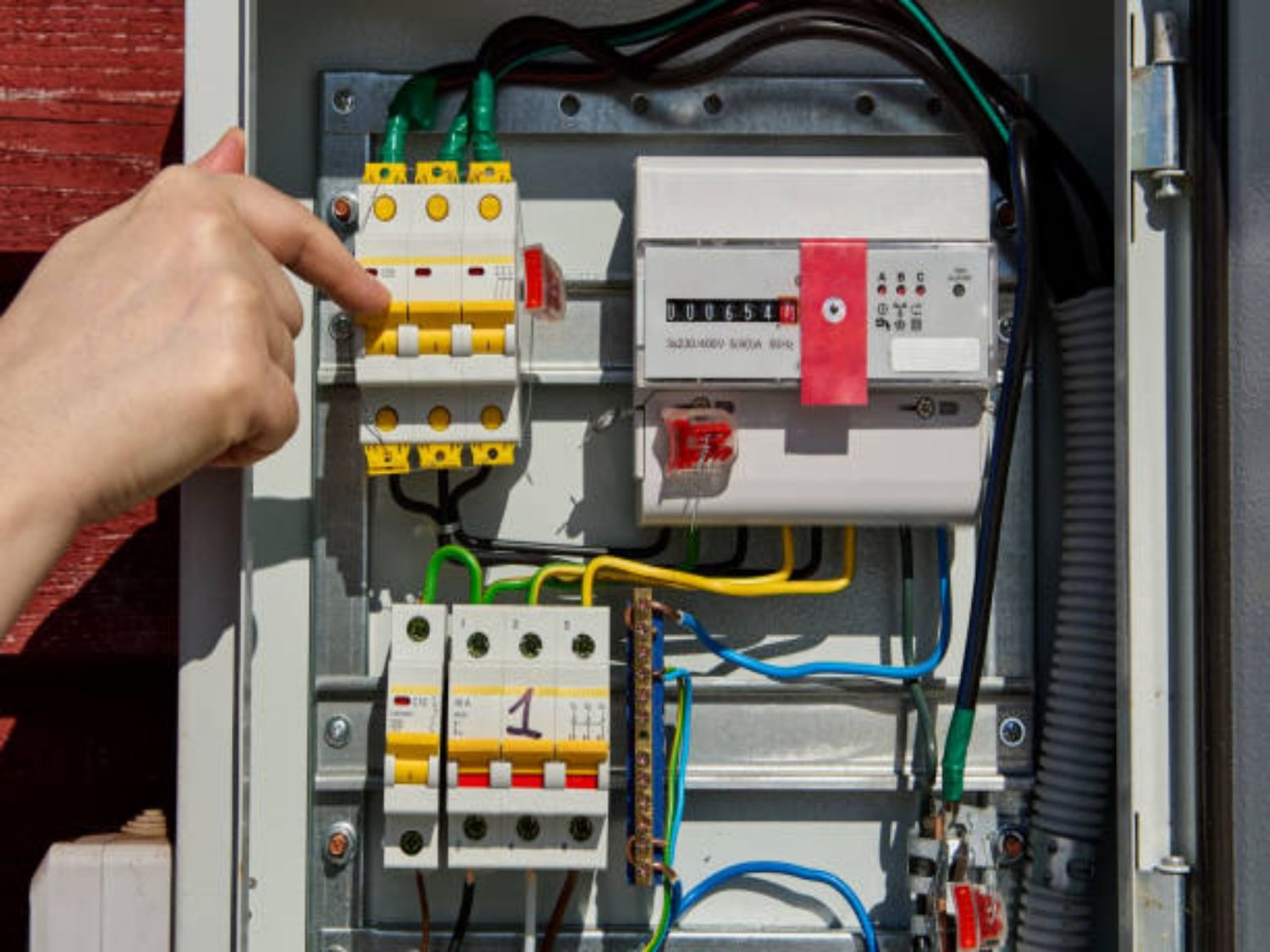

When it comes to electrical systems, contactors play a crucial role in controlling the flow of electric current. One such important type of contactor is the 60947 4 contactor. In this article, we will delve into the different aspects of the 60947 4 contactor and its significance in various applications.

Understanding the 60947 4 Standard

The 60947 4 standard is a specification defined by the International Electrotechnical Commission (IEC) that outlines the requirements for low-voltage switchgear and controlgear. Specifically, 60947 4 focuses on contactors and motor-starters. These devices are widely used in industrial, commercial, and residential settings to control motors, pumps, compressors, and other electrical loads.

The Functionality of a 60947 4 Contactor

One of the key functions of a 60947 4 contactor is to establish and interrupt electrical power circuits. It consists of a set of contacts that can be opened or closed by an electromagnet. When the contactor is energized, the contacts close, allowing current to flow through the connected load. Conversely, when the contactor is de-energized, the contacts open, interrupting the current flow.

Benefits of Using a 60947 4 Contactor

There are several advantages to using a 60947 4 contactor in electrical systems. Firstly, these contactors are designed to handle high current ratings, making them suitable for heavy-duty applications. Additionally, they offer enhanced durability and reliability, ensuring smooth and efficient operation. Moreover, the 60947 4 standard ensures that these contactors meet stringent safety requirements, providing peace of mind to users.

Applications of 60947 4 Contactors

60947 4 contactors find applications in a wide range of industries. They are commonly used in motor control centers, industrial machinery, HVAC systems, lighting systems, and building automation systems. In these applications, contactors are responsible for starting, stopping, and protecting motors and other electrical devices.

Considerations for Choosing a 60947 4 Contactor

When selecting a 60947 4 contactor for a particular application, several factors need to be considered. These include the current rating, voltage rating, coil voltage, and number of poles required. It is important to choose a contactor that matches the specific requirements of the system to ensure optimal performance and longevity.

Installation and Maintenance of 60947 4 Contactors

Proper installation and regular maintenance are crucial for the efficient and safe operation of 60947 4 contactors. It is essential to follow the manufacturer's guidelines for installation, including proper wiring and connection techniques. Regular inspections and cleaning of the contactor's contacts are also necessary to prevent any potential issues and ensure optimal performance.

Common Issues and Troubleshooting

While 60947 4 contactors are highly reliable, they may encounter issues over time. Common problems include contact welding, contactor chatter, and coil failure. If any of these issues occur, it is important to consult a qualified electrician or technician for troubleshooting and repairs to avoid further damage or safety risks.

Upgrading to 60947 4 Contactors

If you have older contactors in your electrical system, it may be worthwhile to consider upgrading to 60947 4 contactors. The improved efficiency, reliability, and safety offered by these contactors can enhance the overall performance of your system and reduce the risk of downtime or costly repairs in the long run.

Conclusion

60947 4 contactors are essential components in electrical systems, providing reliable and efficient control of electrical loads. Understanding their functionality, benefits, applications, and maintenance requirements is crucial for ensuring optimal performance and safety. By choosing the right contactor and adhering to proper installation and maintenance practices, you can maximize the lifespan and performance of your electrical system.