Table of Contents

DC power contactors play an integral part in this arena, their importance compounded when applied in applications where precision, reliability and efficiency are of utmost concern. Meanwhile, electrical engineering can be complex. In particular, distinguishing between Direct Current (DC) and Alternating Current (AC) systems denotes more than simply their respective flows of electricity

This article dives deep into the heart of DC power contactors, exploring their functions, varieties, constituent elements, comparative advantages, and versatile applications - all through an approach which transcends conventional thought while echoing with modern professionals leading today's electrical innovations.

Deciphering the DC Power Contactor

What is DC contactor?

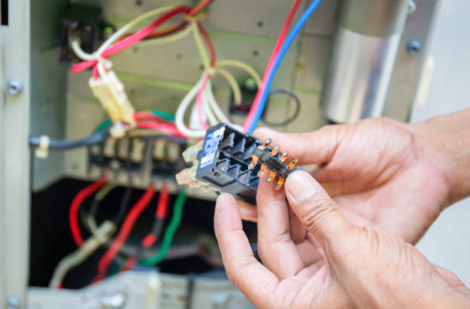

A DC contactor is an electromechanical switch designed specifically to regulate power circuits within DC systems. It controls electrical power flow between circuits by interrupting and establishing it again - thus managing operational dynamics of high-current loads (see high-voltage DC contactor for more detailed cases.)

A key characteristic of a DC contactor lies in its ability to handle unique challenges associated with direct current, such as maintaining performance under constant voltage conditions and managing electric arc extinguishment when contacts open or close within the contactor

Key Features of DC Contactors

- High Current Capacity: Designed to control and switch high current loads efficiently.

- Arc Suppression: Incorporate advanced features to manage and suppress electric arcs that occur when interrupting DC currents.

-

Durability: Engineered for reliability and longevity under rigorous operational conditions.

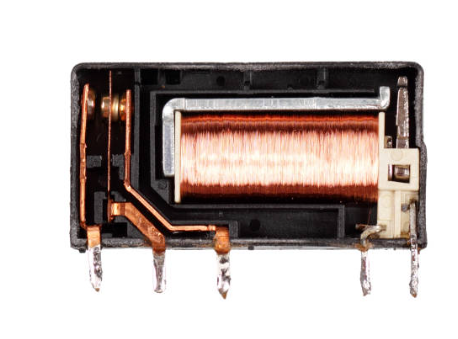

Dissecting the Device: Components of a DC Contactor

A typical DC power contactor comprises several key parts, each playing a vital role in its operation:

- Coil: The driving force, an electromagnetic coil activates the contactor when current flows through it.

- Contacts: The heart of the contactor, where the circuit is made or broken. It includes stationary contacts (fixed) and moving contacts (movable).

- Arc Suppression Methods: Devices or techniques employed to extinguish the arc that forms when the contacts separate.

- Enclosure: A protective housing that shields the internal components from external elements and enhances safety.

Meanwhile, you can also get high-quality contactor switches from reliable suppliers.

Exploring Contactor Types: A Spectrum of Choices

The landscape of electrical contactors is diverse, with each type tailored to meet specific operational exigencies like the DC contactors do. Herein, we delve into the principal categories:

Magnetic Contactors

These are the stalwarts of the contactor world, relying on electromagnetism to drive their operation. When current flows through the contactor coil, it generates a magnetic field, compelling the contacts to close and thus complete the circuit. Their robustness and high current handling capacity make them ideal for heavy-duty applications.

Solid State Contactors

At the cutting edge of contactor technology lie solid-state contactors. These devices leverage semiconductor elements to switch circuits, eschewing mechanical movement entirely. Their appeal lies in their longevity, minimal maintenance requirements, and swift operation, making them suitable for applications where rapid switching and reliability are crucial.

DC Contactor VS AC Contactor

What is the difference between AC and DC contactors?

AC contactors are widely used across many applications; however, DC contactors offer unique benefits, particularly in environments that primarily use direct current:

DC Contactors excel at mitigating arcs, which can be more pervasive in DC circuits due to current's unidirectional flow.

What makes DC contactors stand out?

Operational Efficiency: DC contactors excel at managing high voltage and current applications with their superior efficiency, handling power distribution with grace.

Their Application Spectrum: Where DC Contactors ExcelDC contactors have proven invaluable across a diverse array of industries and applications, underscoring their versatility:

The Application Spectrum: Where DC Contactors Shine

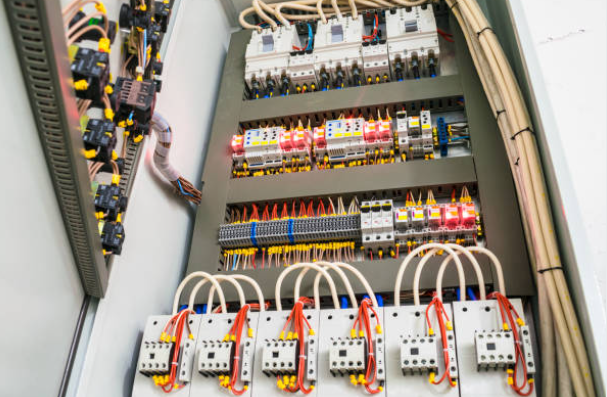

The utility of DC contactors spans a broad array of industries and applications, underscoring their versatility:

- Renewable Energy Systems: They are instrumental in the optimal distribution and management of power in solar and wind energy systems.

- Electric Vehicles (EVs): DC contactors play a critical role in the efficient and safe distribution of power from the battery to the motor, a cornerstone of EV technology.

-

Industrial Automation: From manufacturing lines to robotics, DC contactors ensure the seamless operation of machinery, embodying the nexus between power management and technological advancement.

In Conclusion: Mastering DC Power Contactors

The journey through the world of DC contactors reveals a landscape where innovation meets utility. For professionals navigating the complexities of electrical and power management systems, an in-depth understanding of DC contactors—spanning their types, components, advantages, and applications—serves as both a foundation and a frontier for exploration.

In embracing this knowledge, one not only hones the capacity to innovate but also to contribute to the evolution of electrical engineering, paving the way for advancements that resonate with efficiency, sustainability, and the relentless pursuit of excellence.